Selvedge Printing Machine

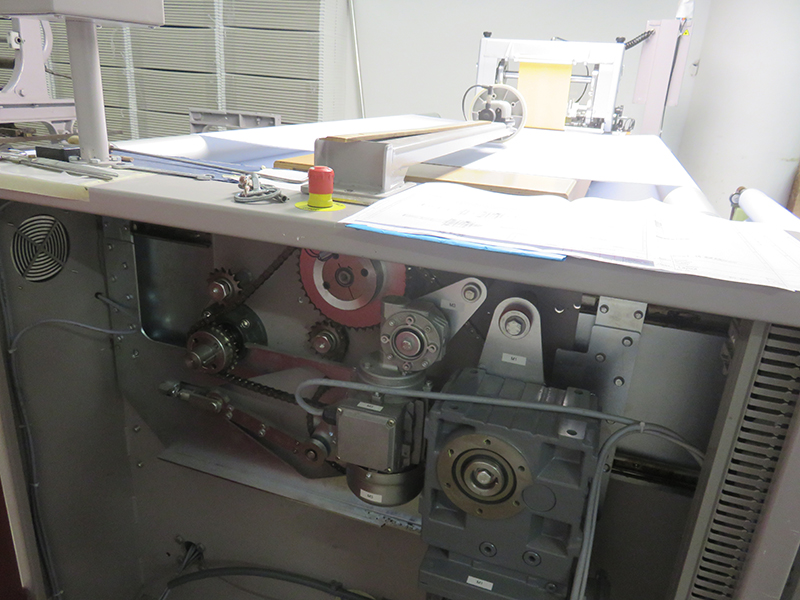

The importance of selvedge printing is constantly increasing and therefore places new demands on the design of equipment. The challenges of selvedge printing are solved by the MAAG Selvedge Printing

Machine SKD, which operates fast, easily and above all cleanly. It is the only machine on the market capable of printing gold or coloured lettering by a flat heat process on the standstill fabric flow. It will print equally well on the finest silk or the coarsest cotton cloth. Light to medium heavy woollen goods are successfully processed. As all textiles are not of the same thickness, it is necessary to adjust the pressure of the printing block and this variation is easily made by means of two eccentric cams. The standard machine is built to operate from roll to roll but can, if required, accom-modate other working system

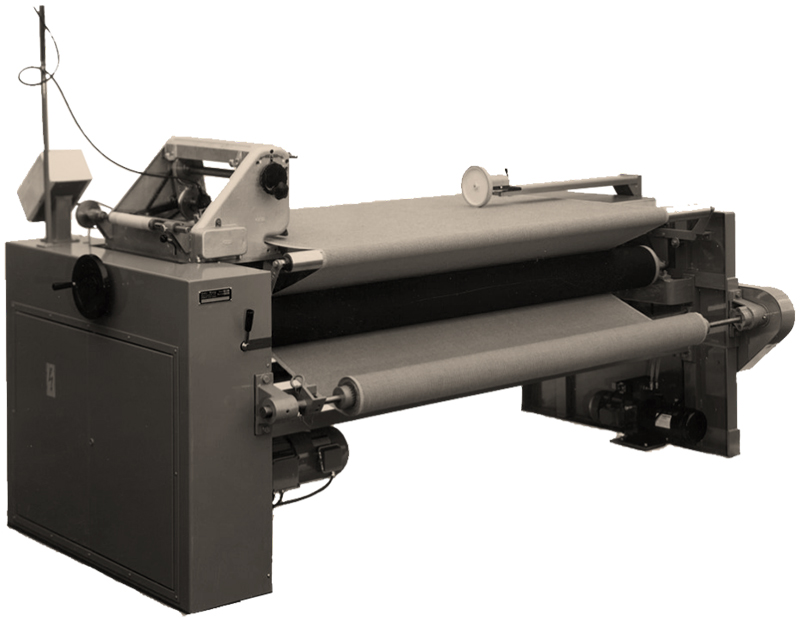

Printing system

The cloth from the feed roll runs over a drawing-off roller, then over two guide rollers which oscillate together, and then over a further drawing-off roller before being rolled up again..

Printing takes place between the two oscillating rollers and that part of the cloth which will be printed on is momentarily stopped while the impression is being made.

While the cloth movement is thus stopped, the feed roll, drawing-off rollers and take-up roller continue to rotate and ensure even and quiet running of the machine.

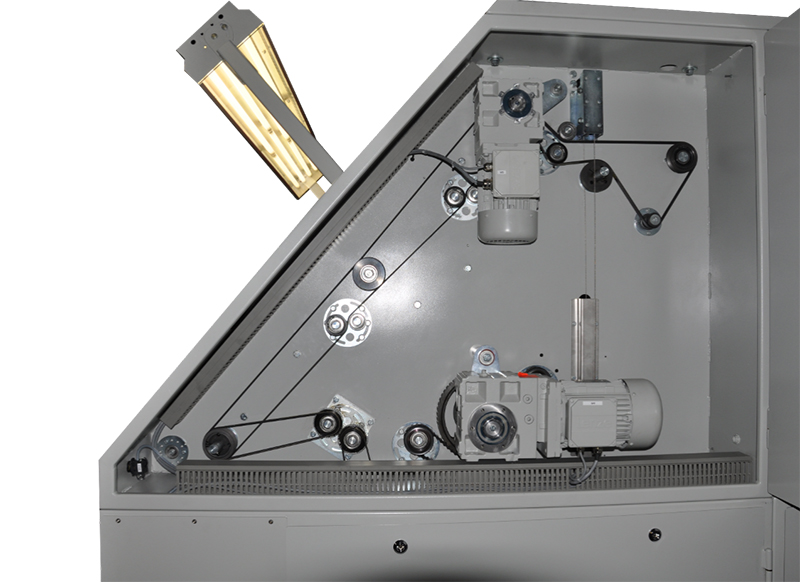

The printing machine uses fl at type and the copy may be made up of normal printing type letters.Therefore, no special blocks need to be engravedas is the case with the rotating type of machine

This feature considerably increases the versatility of this machine and caters to the special needs of each customer.

The maximum printing length is 22 cm (8 5⁄8“) and height 2 cm (25⁄32“).

The printing set is electrically heated and, as different foils and also different textiles require different temperatures, the printing set is supplied with a thermostatically controlled heating element and fi tted with a thermo- meter. The latter permits the operator to select the proper temperature for every condition.

The foil is fed automatically from the roll and can be adjusted accurately according to the type height, waste thus being eliminated. All these components can be removed for cleaning and checking without the use of tools, just by a few simple hand movements

By means of straightforward arrangement the machine can be set to print every 1, 2 or 3 metres or yards.

For a small additional cost the machine can be supplied with extra gears which enable it to print in metres as well as yards