FH

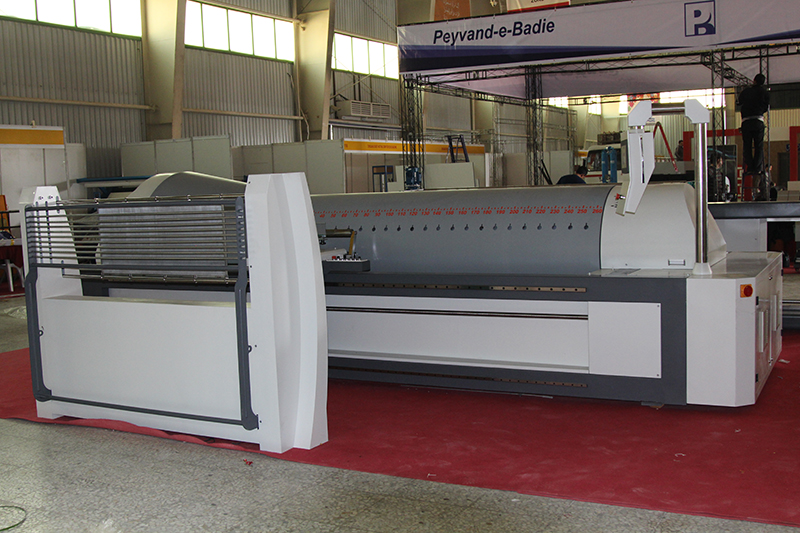

- Mechanical features

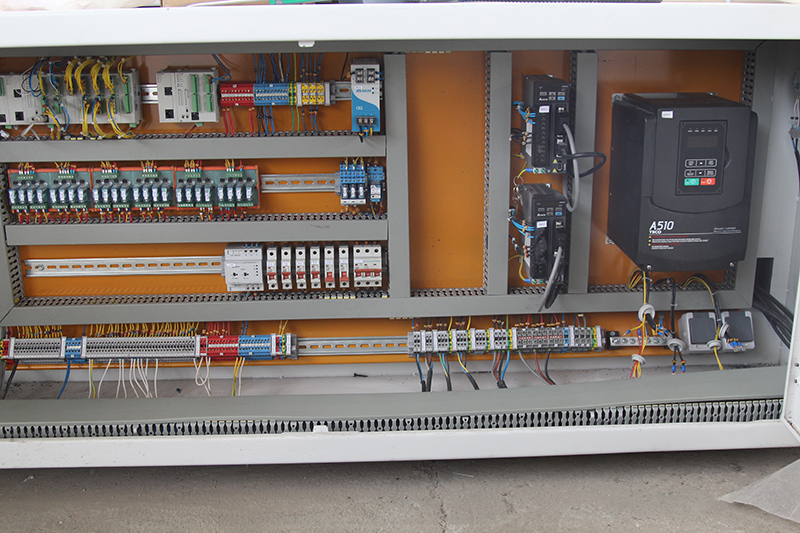

- Electrical features

- Highlight features

- Optional features

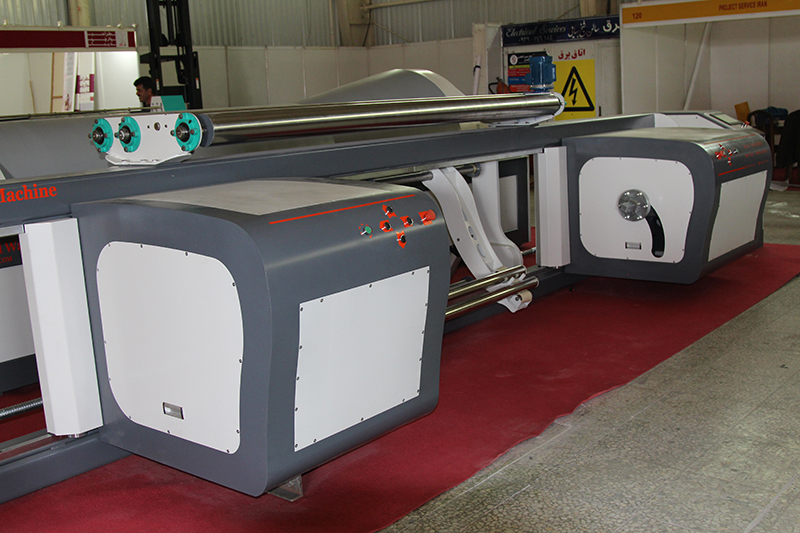

- pictures

- videos

- catalogue

- layout

Mechanical features

| Useful warping width | 230-360 cm |

| Maximum beam flange | 1000 mm |

| The length of slope cone | 125cm |

| Slope angle | 11° |

| Maximum warping speed | 1000 m/min |

| Maximum beaming speed | 300 m/min |

| Band width | 45cm |

| Drum diameter | 90 cm |

Electrical features

Equipped with 10'' fully color touch screen monitor

Displaying the reed table movements along with X and Y axes, simultaneously

Controlling the constant linear speed of yarn during warping

Adjusting the speed of drum and beam in an adjustable time

The possibility of programming middle comb movement for leasing, automatically Servo

*Having two HMI monitors to show and control machine's parameters in beaming and threading parts for fast troubleshooting

Using servo motor for the movement of X and Y axes in reed table

Highlight features

Using network system in the designing of machine automation

sing laser sensor to increase the accuracy in yarn breakage warning markers

Installing helical fans to cooling linings

Installing helical fans to cooling linings

Using 18.5 KW inverter for beam motor

Using 11 KW inverter for drum motor

Using tension sensors for measuring the tension in beaming and threading from creels

Reed table driven on precise ball screw with accuracy of 0/001 mm

Equipped with tension roll in beaming parts

Using polished rolls with mild steel in beaming parts

Using proportional valves to control yarn tension in beaming, automatically