D&S

- Mechanical features

- Electrical features

- Gearboxes technical features

- General features

- Highlight features

- Videos

- catalouge

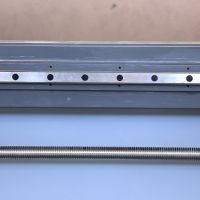

Mechanical features

| Useful warping width | 260-360 cm |

| Maximum beam flange | 1250 mm |

| Slope cone length | 160cm |

| Slope angle | 11° |

| Maximum warping speed | 400 m/min |

| Maximum beaming speed | 300 m/min |

| Band width | 110cm |

| Drum diameter | 100 cm |

Electrical features

The possibility of slope changing four times in the first band

Controlling linear speed of yarn during threading

Displaying rolled yarn length around drum

Equipped with intelligent servo motor and servo drive

Equipped with 5 PLC with high ability (delta)(Delta)

Determining the distance of bobins from controllers

Equipped with 3 protecting systems in beaming

Displaying rotation speed of drum in RPM (c/m)

Displaying the reed table movements along X & Y axes, simultaneously

Displaying the number of rolled yarn cycles around the drum with the accuracy of 0/1 cycle

Displaying yarn linear speed in m/min

Equipped with cold waxing system and controlling digital speed by AC drive AC

The possibility of reforming broken yarn during beaming and threading

The possibility of programming middle comb movement for leasing, automatically

The possibility of transferring machine software information and troubleshooting with fax modem

Determining the slope no for different kind of yarn, no need of information about no, compression and type of yarn

(Equipped with powerful AC drive to adjust the speed of beaming with the power of 50 HP (European

The possibility of programming middle comb movement in order to prevent the cutting of yarn with variable speed

Minimizing the operator's errors due to designing form of machine and its controlling systems

The possibility of programming reed table comb movement in order to prevent the cutting of comb blades

Displaying all emergencies of machines in English and Persian, separately

Equipped with 10" fully color touch screen in threading and beaming

Gearboxes technical features

Drum has planetary gearbox

The power of protection gateway motor is 1.5 KW KW

The power of creel wagon motor is 1.5 KW

Using two 1.5 KW motors for jaws movement (2 عدد)

Using two 1.5 KW motors to control the creel yarn tension ( )

The power of waxing motor and pump motor are 0.75 and 2.2 KW , respectively

The power of beaming inverter and drum inverter are 37 KW (European) and 15 KW (European), respectively.

The power of beaming motor and drum motor are 37 KW and 15KW (European), respectively

General features

Maximum speed of warping is 400 m/min

Equipped with pneumatic brakes with the ability of adjusting tension and brakes time during the yarn breakage

Adjusting the speed of drum and beam in an adjustable time

Adjusting the ordering sequential bands around the drum with accuracy 0/1 mm

Adjusting of first warp band place over the drum, fully automatically

Equipped with special reed table for smoothing band surface during rolling, and creating minimum distance between drum and roller

Observing yarn liner speed during the rolling, automatically

Separate beamer –frame, from side- frame

Having pneumatic jack for putting beam up and down

Highlight features

Drum is resistant in confronting with high tension yarn because of its designing

Using sensitive sensors for detecting slope with high accuracy

In order to use of direct warping, chasis withdrawal is possible

Using AC servo motor for the main movement of machine along with x and y axes

Having thermal sensors for measuring the linings temperature and activating cooling fans which are programmable by operator

Equipped with system for measuring and displaying yarn tension during beaming

No need of reeding in sectional and directional warping due to its specific designing

Equipped with tension roll in beaming part for smoothing the warp surface

Having anti-abrasion and antistatic-electricity roller for implementing pressure in direct and sectional warping

Having protecting gate in front of beam

Having programming start system in beaming

Expanding comb on the beam has following capacities:

Using pneumatic system for putting expanding comb up and down (this case can reduce reeding time from 3 hours to 2 minutes) DC

Left and right movement to adjust comb position by the use of gearbox motor DC

Determining the distance of bobins from creel controllers with the use of gearbox motor

Zigzag movement with the use of pneumatic system, automatically

Unique features of waxing system are as follow

Ability to display and control the amount of used wax which is programmable by machine

Using sensitive sensors to display the amount of used wax, accurately

Ability to recharge the machine wax storage (when it is empty) from the main storage tank, automatically

Having close cycle in waxing system for homogenizing the material and separating yarn lint in tank filter

Following features distinct this machine from directional warping machine

Ability to warp in directional and sectional state

Precise control on the yarn tension from creels

Replacement of yarn in creel, decrease from 8 hours to 20 minutes

Displaying precise tension during beaming by machine

High speed of warping in beam MAX 200 m/min

Equipped with beam-to-beam system

The possibility of leasing in directional state

The possibility of beaming from beam on the drum when beam is broken or cracked during rolling

Creel features

Unique designing of creel to facilitate reeding as septet and octet rows

Equipped with speed controlling wagon to facilitate operator's action in replacement of bobins inside the creel

Designing powerful fans to clean up the creel floor

Equipped with cutter system to cut creel yarn

Equipped with precise electronic system for adjusting automatic tension of creel yarn

Rotatable bases of bobins holder, manually

Ability to adjust the distance between tension controllers and bobins with pneumatic system

Ability to adjust yarn tension from the creel

HMI 7” Equipped with yarn breakage warning system with laser sensors

Equipped with engine and gearbox to determine the distance of bobins from controllers

Displaying the row of breakage yarn with optical markers

Sequential display of optical markers

Equipped with 7 HMI monitors to display temporary position of controllers' tension and fulfill new changes

{tabPictures}